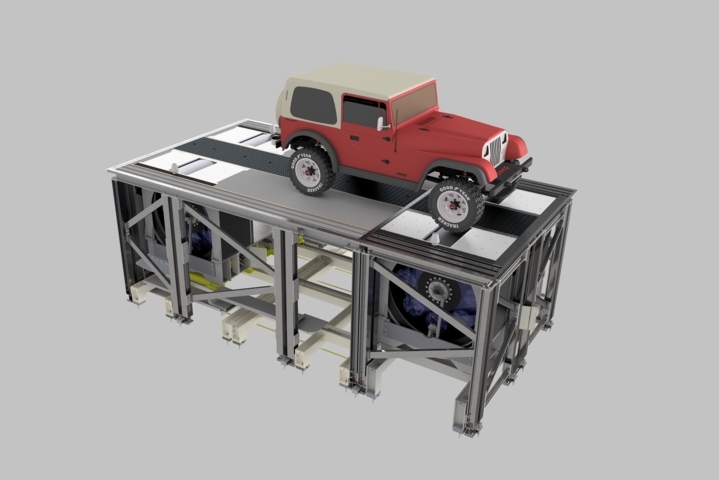

Dynosaur 48" 4WD Compact HD

48" rolling road test bench for heavy vehicles with 2 or 4 wheel drive

The rolling road test benches manufactured by Control Sistem are designed to guarantee that any type of testing can be performed, faithfully simulating the physical conditions that can be obtained on the road but guaranteeing the repeatability of the laboratory, for example: validation cycles: WLTP, NEDC, etc.; Climate tests; Electromagnetic compatibility tests; Power tests; Vehicle component tests; R&D tests. In particular, Dynosaur 48" 4WD Compact Heavy Duty is the rolling road test bench capable of testing heavy vehicles up to 7,500 kg. It mechanically consists of two modules: one fixed and one shifting, so that the bench can be adapted to vehicles with different wheelbases, but it can also accommodate vehicles with only two drive wheels without any problems. Each one of the two modules features a single roller with a diameter of 48" (1,219 mm). The rollers that form the fixed and shifting modules have a surface coating that optimises the coefficient of friction between rollers and tyres, simulating the condition of a wheel on tarmac. The rollers are powered by dedicated inverter panels, equipped with energy regeneration functions; the power flow can therefore be realised both in the incoming direction and towards the grid, significantly reducing the plant's energy costs. The rolling power test bench is typically characterised by CONTROL SYSTEM per axis of 250 kW (however, it is possible to have axes with lower or higher powers) and can work in an environment with a temperature between 5 and 60 °C, but on request it can be equipped with the appropriate instrumentation that allows the working temperature to be expanded to -30°C. The rolling road test bench is integrated with a dedicated automation software that allows intuitive use of the bench starting from the launch of test cycles through to data management and report generation in line with the standards of the chosen validation cycle. The software typically consists of a distributed control architecture in a 'master and slave' architecture; the architecture is designed so that it can be easily adapted to the customer's needs or integrated into any existing automation system. The rolling road test bench is certified according to the requirements of the "WLTP standard".

The rollers making up the fixed and the translating modules are characterized by a surface coating that allows to optimize the coefficient of friction between the rollers and the tires, so as to simulate the condition of the wheel on the asphalt..

The bench is controlled by two asynchronous electric motors (one for each module) located in the centre of the rollers, mounted with an oscillating casing and a load cell. Each electric motor is controlled by a regenerative inverter, thus guaranteeing an extremely low energy consumption.

The rollers are placed on a high rigidity steel frame, which can be installed over a seismic mass or more simply on a plane suitable to support both the weight of the bench mechanics and the vehicle ones.

Dynosaur 48 ”4WD Compact HD is equipped with an automation system able to manage all the components of the roller bench. The intelligence of the automation system is mainly based on PLC processors and on the INT9000 real-time software development environment.

The automation system is synthetically composed of an automation drawer (DBSro) able to manage the electric motors and consequently the behaviour of the rollers, the Driver AID system which allows the driver to follow the speed profile of the test cycle and a management application (CSrolls) supervising every aspect of the bench and the test parameters.

Use of the test bench

Cycles of emission measurements according to the following international regulations:

• ECE / EUDC / NEDC European regulation

• FTP75 / SFPT (US06, SC03) American regulation

• 10-15 modi / JC08 Japanese regulation

Cycles of power measurements in static and dynamic conditions:

• Endurance tests

• Consumption tests

• Performance tests

• Driveability tests

Main function

• Road load simulations in accordance with the vehicle parameter settings

• Operation at constant speed with power measurements

• Determination of the vehicle power curve with ascending or descending ramps

• Automatic Coast Down cycle verification

• Automatic bench calibration cycle

- Rollers diameter 48” (1.219 mm)

- Maximum vehicle weight 5.000 kg

- Maximum load per axle 3.500 kg

- Load cell (full scale) 10 kN

- Load cell accuracy ± 0,1

- Encoder type 1.024 pulse

- Encoder accuracy ± 0,08

- Working temperature range from 5 to 60 °C

- Working temperature range with climatic equipment from -30 to 60 °C