POWERTRAIN AUTOMATION

Automation system for powertrain test rooms

A fully automated Powertrain test cell requires an automation system capable of managing not only the electric motors operations (two or four depending on the vehicle type: 2WD or 4WD), but also of all the systems and devices in the cell itself.

To meet this need, Control Sistem has developed over the years an automation architecture with a pyramid structure, at the top of which there is a supervision system capable of communicating and therefore controlling all the subsystems that make up the pyramid and, more generally, to interface with the entire test cell.

Typically, the cell's subsystems consist of the two/four electric motors, the automation system which controls the electric motors, and the signal acquisition system. The automation developed by Control Sistem allows you to have a single automation architecture for the Powertrain test cell or individual modular components, based on PLC and characterized by such flexibility as to guarantee communication with other automation systems on the market.

All of this was possible mainly thanks to the INT9000 environment evolution with the aid of the best PLCs on the market. INT9000 is a real-time software created internally in Control Sistem, extremely flexible and obviously easy to use. Naturally all the automation system applications have been created with it.

Intelligent automation systems for automotive testing

Control Sistem provides test rooms equipped with sophisticated automation systems capable of performing any reliable and innovative automotive test. The test rooms are fully automated environments, which allow the execution of high-level tests on the entire transmission system. Our cutting-edge technology and machinery allows us to check the correct functioning of the system that transmits the motion generated by the engine to the vehicle's wheels in automated and innovative test rooms.TeCAS – Test Cell Automation System

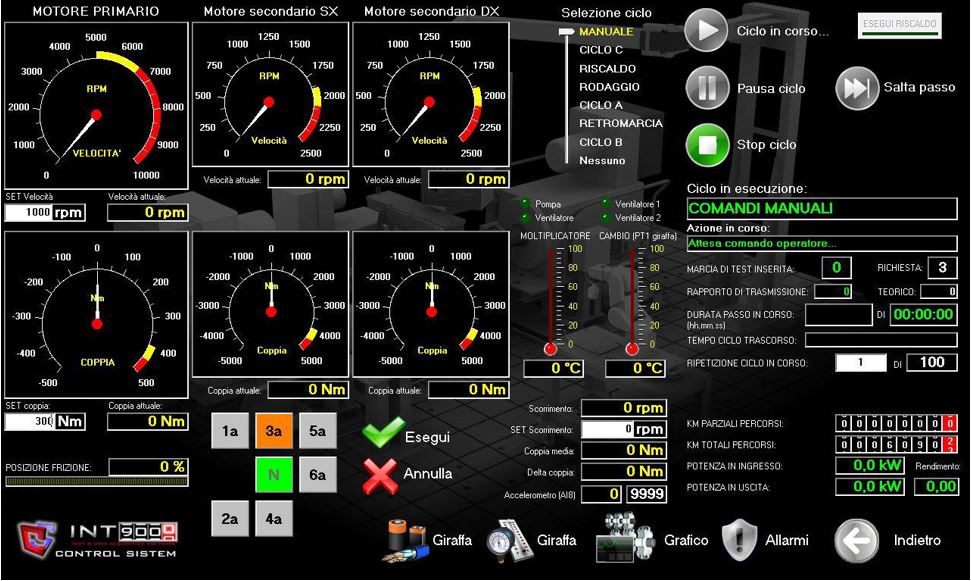

TeCAS is the pyramid vertex able to manage, monitor and command all the components of a transmission test cell. The application is installed on the cell’s PC and the typical INT9000 user-friendly interface allows engineers and operators to easily monitor the transmission unit, to perform the main automatic cycles of homologation and not and to manually reach the working points of the tests. On the application main page, a real-time graphic support allows the monitoring of the transmission main dynamic variables.

The application also allows you to identify and memorize the transmission systems under test, defining configuration files that the user can compile and recall whenever the transmission is re-installed in the room.

TeCAS' management capacity is also shown in terms of cell safety. The application, in fact, allows the user to set limit values for many quantities involved and to associate alarm thresholds with consequent safety actions (gradual stop of the system, plant stop, etc.), also settable by the operator.

TCM – Test Cell Monitoring

TCM is an application intrinsic to TeCAStr, created with the aim of displaying on a single dedicated screen, all the variables or signals coming from the transmission test room: temperatures, pressures, rpm, measurements by room measurement instruments, etc.

The application hardware consists of a "box" for collecting signals or, more commonly speaking, a Boom Box: a system for acquiring input and output channels. The Boom Box is equipped with an articulated arm constrained to the wall, capable of allowing the positioning of the signal collection box in the most convenient point, inside the test room.

DBS – Dynamic Braking System

DBStr is the automation unit that is in charge of the three-phase asynchronous electric motors complete management:

- engine start

- regulation modes

- safety

The unit is made of a 19” rack consisting mainly of the control electronics, present inside it, and a front panel pc with touchscreen technology, which allows the operator to conveniently modify the main parameters useful for controlling the three electric motors, as well as monitoring the main variables of interest (torque, speed, etc.).

DBS can be interfaced with the upper automation system (regardless of whether it is TeCAS or another cell control system) either via digital / analog signals or via Modbus Ethernet protocol.

MDH – Master Device Handler

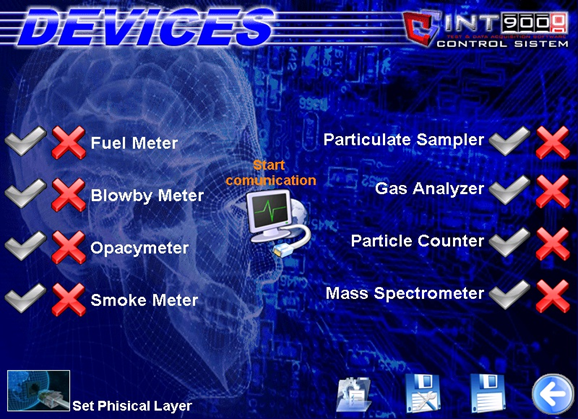

MDH is an interface dedicated to the management and control of all peripherals and measuring devices inside the transmission test room.

The unit consists mainly of a PLC and a panel PC with touchscreen technology and is equipped with all the necessary cards to guarantee the connection between the system and the individual instruments, via Ethernet and serial protocols.

Each individual device connected to MDH has a dedicated section available, which allows the user to access manual use of the individual instrument, as well as monitor its status and acquire detailed information on any alarms and operating anomalies.

Like all the components that make up the automation, MDH is able to communicate with any superior supervision system, including, of course, TeCAS. In the latter case, it is possible to use the main commands of the instruments in communication with MDH, directly from TeCAS, which can also control them automatically during the execution of a cycle.

MDH is also an expandable system: it is possible to implement the existing structure with all instrument drivers not yet present within the application.