EACS – Engine Altitude Condition Simulator

Altitude simulator for endothermic engines

The altimetric simulator (EACS) is an innovative system that allows tests to be carried out on internal combustion engines by simulating conditions of altitude above sea level that differ from the actual conditions at the site where the test is actually performed. This allows the engine's behaviour to be tested under different altitude conditions in a range from 800 metres below sea level to 5,000 metres above sea level.

Thanks to a very fast and reliable regulation system, the altitude simulator (EACS) is able to maintain the pressure value set in the simulation software by adapting to any variation arising from the engine's operating requirements. The system allows any type of test to be carried out in stationary, transient conditions or to accurately simulate uphill or downhill routes.

Control Sistem is synonymous with innovation in the field of altitude simulation testing

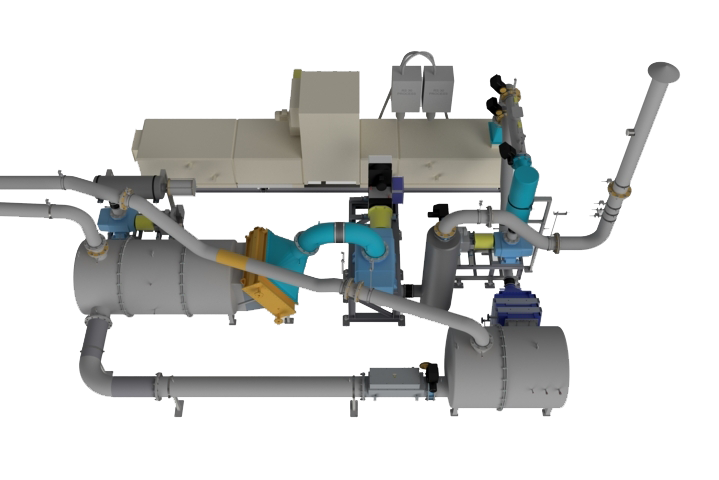

Before the introduction of the altimetric simulator (EACS) in engine and vehicle test rooms, and more simply in the world of automotive testing, altitude simulation tests were carried out in barometric chambers. These had to be able to withstand the enormous mechanical stresses resulting from the pressure difference between the inside and outside of the chamber. The new technology introduced with the altimetric simulator (EACS) removed the structural problems of barometric chambers, providing greater flexibility of installation. The concept of altitude simulation has been extended to all types of engine and vehicle test rooms regardless of the height above sea level at which the test room is located.EACS technical solution consists in providing the desired pressure level within a volume of adequate capacity. This is possible thanks to a pump system able to obtain stable pressure conditions during the transients of the engine, also following rapid variations in the flow rate of combustion air, fuel and exhaust gas. The intake and exhaust ducts of the engine are then connected to the EACS volume through sealed connections.

The combustion air can also be regulated in temperature and humidity and thanks to high precision sensors, continuous and accurate monitoring of these conditions is guaranteed. EACS is available for different engine sizes: from small engine cars (light duty applications: maximum 1.200 kg/h) to heavy industrial vehicles (heavy dutyapplications: maximum 2.400 kg/h).

The final configuration of the system is studied in relation to the specific needs of the customer, not only based on the engine to be tested, but also according to the spaces available for positioning the components.

The intelligence of EACS resides entirely within a software application created in INT9000 development environment, which guarantees its full interface with any test cell automation system and makes the application easy to use.

Advantages

- Possibility to execute dynamic tests

- Possibility to simulate altitude both higher and lower than the ambient one

- Very reduced electric consumption, thanks to the use of regenerative inverters

- It can be placed in existing test cells

- Possibility to place its components in different room

- Personalized design

- User friendly software (INT9000)

- Complete control through AK protocol

- Maximum flow rate 2.400 kg/h

- Minimum pressure simulated – 500 mbar (about 5.000 m above the sea level)

- Maximum pressure +100 mbar (about 800 m under the sea level)

- Altitude variation speed 250 m/s

- Pressure stability (stationary conditions) ± 1 mbar

- Pressure stability (dynamic conditions) ± 4 mbar

- Temperature range from -30 °C a 60 °C

- Relative humidity range from 5% a 95%

- Temperature stability ± 1 °C

- Relative humidity stability ± 3%

- Remote control AK protocol