PSS-20

Particulate Sampling System

Particulate sampling system for endothermic engines

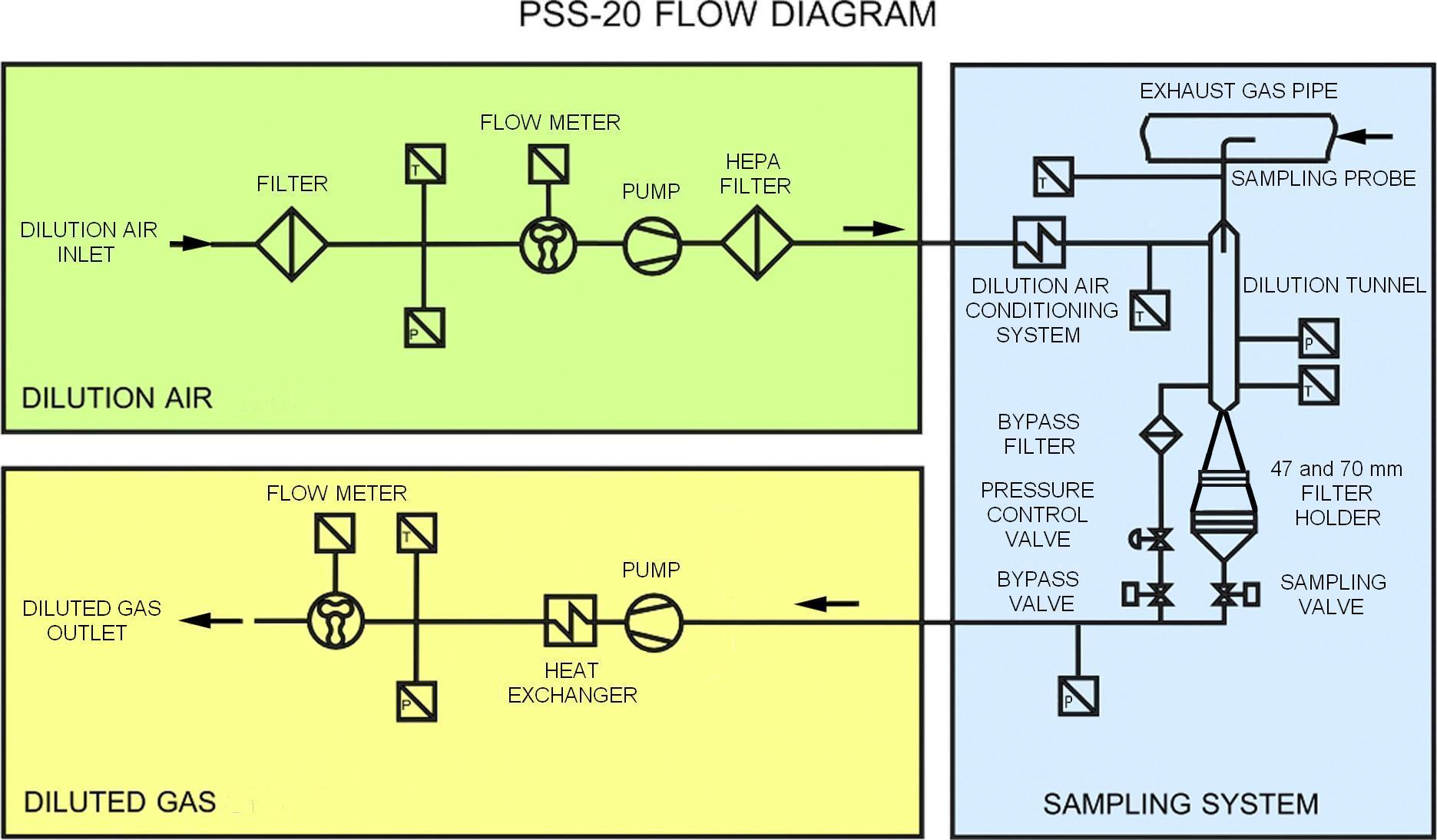

PSS-20 is a particulate sampling system based on the partial flow method and variable dilution. It satisfies the specifications contained in all main European and American regulations for the homologation of diesel engines, from light duty up to heavy duty, both on-road and off-road.

The PSS-20 is capable of sampling in both stationary and dynamic conditions ensuring perfect correlation with the total sampler (CVS). The partial sampling principle makes it possible to apply the PSS-20 for all engine sizes, from ultra-light to marine engines, and it can be used as a secondary diluter in CVS systems.

PSS-20 is mainly composed by two parts: the control cabinet and the trolley containing the dilution mini-tunnel. The cabinet is commonly placed in the control room; the unit is controlled by a standard PC connected to the cabinet by means of a common Ethernet cable. The trolley is equipped with wheels and it has a flexible mechanical structure, which allows it to be adapted to any configuration of the engine exhaust gas pipe. PSS-20 uses ambient air as dilution air. The connection with the compressed air plants of the building is not necessary, it only needs 230 V AC power supply.

The mechanical unit of PSS-20 is equipped with low inertia volumetric meters, connected to variable displacement pumps. This configuration makes it possible to obtain a very low response time in transient conditions and it guarantees great stability over the time, in fact it is only necessary to recalibrate the system once a year.

PSS-20 can be equipped with a sensor for continuous particulate matter reading (PPM), which operates by electrically charging the particles. Once this reading has been integrated and corrected by means of the indication obtained from the filter, it is possible to know the real-time evolution of the particulate matter during the test.

PSS-20 is one of the of mainly widespred standard products of Control Sistem. Indeed 250 units are spread aroud the world, satisfaying the leading car manufacturer.

Advantages

- Compliant with the main European and American homologation regulation

- Usable as secondary dilution system

- Adaptable to different engine sizes

Standard references

- Directive 88/77/EEC as amended by 1999/96/EC and 2001/27/EC

- Directive 2005/55/EC and 2005/78/EC as amended by - 2006/51/EC

- 2006/81/EC and 2008/74/EC

- ECE Regulation No. 49, Rev. 3, 04 Series / ECE Regulation No. 49, Rev. 4

- 05 Series and ECE Regulation No. 49, Rev. 5, 05 Series:

- Global Technical Regulation (GTR) No. 4

- Directive 97/68/EC as last amended 2010/26/EC

- ECE Regulation No. 96, Rev. 2, 01 Series

- ISO 16183 (2002), ISO 8178 -1 (2006) and ISO 8178 - 11 (2006)

- U.S. Code of Federal Regulations, Part 1065 as of June 6th, 2011

- Cabinet dimension and weight 600 x 700 x 1.400 mm, 180 kg

- Trolley dimension and weight 1.500 x 300 x 1.000 mm, 70 kg

- Power supply 230 V AC – 2 kW

- Pumps maximum flow 10 m3/h

- Flow meters accuracy ± 0.2% of reading

- Dilution ratio constant o variable

- Transformation time (ISO 16183) < 0.17 s

- Standard regression correlation coefficient [R2] > 0,95

- Filter size 47 mm or 70 mm

- Temperature of diluted gas at filter position from 42 to 52 °C

- Dilution air filter type HEPA

- Dilution tunnel material stainless steel

- Diluted gas speed through the filter between 0.35 and 1 m/s

Options:

- Multiple filter holder (up to 3)

- Automatic filter changer (up to 15 cassettes)

- Multiplexer for connecting up to 4 trolleys

- Automatic certified calibration system

- Heated sampling probe

- Heated mini-tunnel

- Cyclonic separator